Superior performance in low pressure applications.

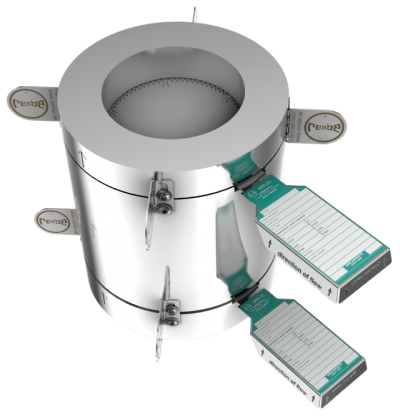

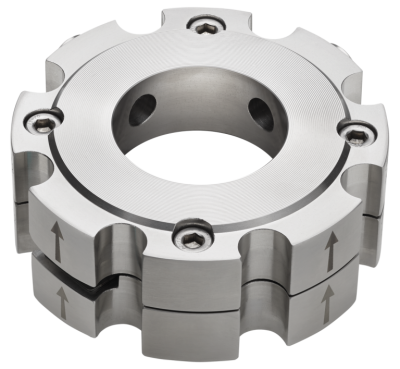

The ODV is a triple-section, forward acting, rupture disc design suitable for a range of low to medium pressure applications. This cost-effective solution comprises three rupture disc elements, a top section burst element, a sealing membrane and an integrated vacuum support, ensuring superior performance and durability across a wide range of process conditions. REMBE®’s unique manufacturing process uses precision laser machinery to create the critical burst elements to define the burst pressure for accurate, full bore, burst opening. The ODV is an excellent pressure relief solution for a wide range of applications in various industry sectors. Compatible with conditions operating as low as 0,05 bar g, the ODV is suitable for gas, liquid and two phase flow applications. The 30° seat, forward acting rupture disc is a non-fragmenting design available from DN 20 to DN 600 (3/4"-24")* making it the ideal solution to fulfil various process conditions.

ODV is primarily used for applications with low to medium pressures, e.g. for gases, liquids and applications with two-phase flows. The disc has a standard operating ratio of max. 80 %*. For burst pressures of less than 1 barg, ODV can be installed directly between flanges or angular rings.

Ersatile, corrosion resistant solution.

The ODV is a versatile, high-performance solution, offering superior corrosion resistance without the incurring the costs associated with a solid metal rupture disc alternative. The critical burst element is isolated from the process media by the sealing membrane minimising the risk of corrosion affecting the burst pressure. This customisable solution enables the selection of the most appro-priate metallic top and bottom section according to the process conditions, keeping costs to a minimum. The sealing membrane, typically a non-metallic fluoropolymer, isolates process media from the critical burst element and enhances the leak rate of the rupture disc, limiting loss of process media during normal operation. The bottom section, vacuum support, ensures the disc is suitable for full vacuum conditions and increased back pressure resistance at low burst pressures without reducing the vent area. Available in a range of standard and exotic metallic elements from stainless steel as standard to tantalum, the ODV is a truly versatile solution offering large vent areas across low to medium burst pressures.

Safe installation and notification of disc burst.

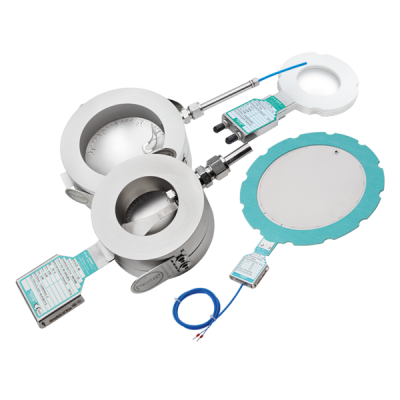

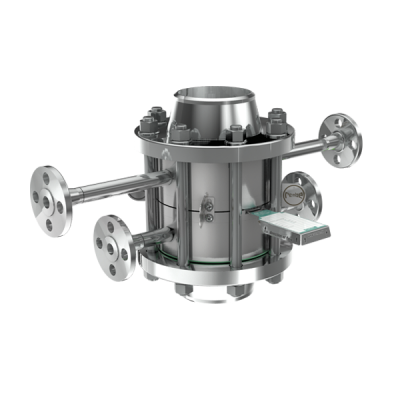

The standard 30° seating arrangement of the ODV ensures accurate performance and installation of the disc into REMBE®’s IG Rupture Disc Holder. The IG Rupture Disc Holder features an inclined seating arrangement creating the optimum seal for the disc ensuring superior leak tight integrity. Alternatively, available with a flat seat design for installation into the IG HL Rupture Disc Holder, and as a special version for installation directly between flanges*. Compatible with a range of REMBE®’s signalling devices including its advanced NIMU signalling device for reliable notification of disc burst.

Advantages

- Suitable for use even with full vacuum due to integrated vacuum support.

- Minimum fragmentation during opening.

- Accurate performance and opening.

- Suitable for a wide range of pressures – maximises positions where disc can be installed across the facility.

- Versatile, corrosion resistant solution – triple-section construction ensures maximum corrosion resistance for long-term, reliable performance.

- Compatible with a wide range of process conditions – versatile cost-effective solution suitable for numerous applications.